Thesis: Alexia Luo

RAMUS v1

RAMUS v1 explores a sustainable design-to-fabrication workflow using biodegradable materials and 4D-printing logic to create large-scale, morphing architectural components—without plastics or synthetic reinforcements.

RAMUS v1

RAMUS v1 explores a sustainable design-to-fabrication workflow using biodegradable materials and 4D-printing logic to create large-scale, morphing architectural components—without plastics or synthetic reinforcements.

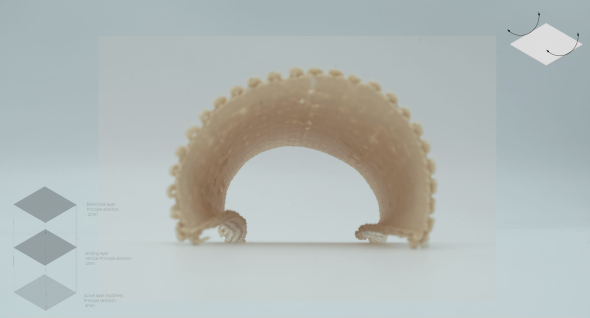

Using a composite made from shrimp-shell chitosan, cellulose pulp, and wood biomass, the project harnesses moisture-responsive deformation to generate self-morphing structures.

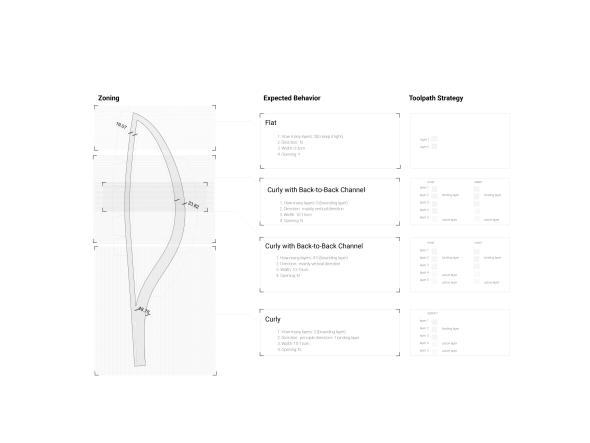

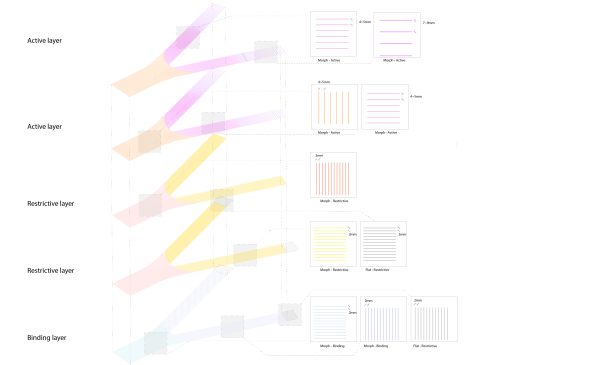

Through systematic experimentation, five key fabrication principles were developed: layer quantity, notch orientation, notch density, toolpath direction, and global geometry. These parameters guide how the material bends, curls, or remains rigid as it dries.

The RAMUS demonstrator tests these principles at scale, using a remote pneumatic extrusion system and custom toolpaths to achieve precise morphing with a single, biodegradable material.

The resulting structure is designed to be carbon-sequestering, zero-waste, and fully compostable, offering an alternative to plastic- or metal-based construction systems.