September 22, 2022

Stuart Weitzman School of Design

102 Meyerson Hall

210 South 34th Street

Philadelphia, PA 19104

Get the latest Weitzman news in your Inbox

Media Contact

Michael Grant

mrgrant@design.upenn.edu

215.898.2539

Researchers including Weitzman's Robert Stuart-Smith have made a swarm of bee-inspired drones that can collectively 3D print material while in flight, allowing unbounded manufacturing for building and repairing structures.

3D printing is gaining momentum in the construction industry. Both on-site and in the factory, static and mobile robots are being deployed to 3D print buildings and building parts in concrete, steel, and lightweight composites.

A new approach to 3D printing using flying robots, known as drones, has just been developed that uses collective building methods inspired by natural builders like bees and wasps.

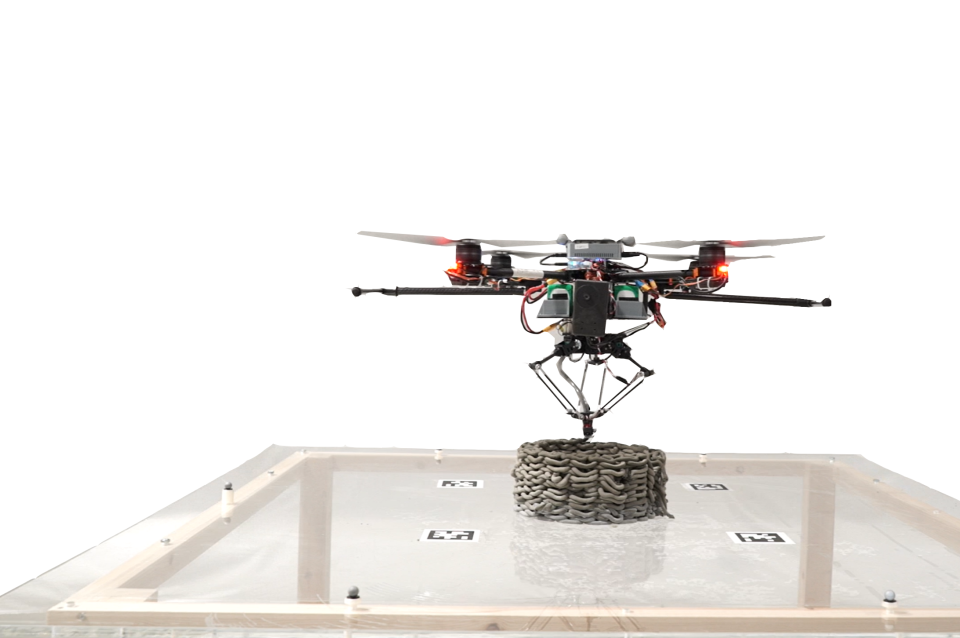

The system, called Aerial Additive Manufacturing (Aerial-AM), involves a fleet of drones working together from a single blueprint. It consists of BuilDrones, which deposit materials during flight, and quality-controlling ScanDrones, which continually measure the BuilDrones’ output and inform their next manufacturing steps. In contrast to alternative methods, in-flight 3D printing is unbounded, unlocking doors that will lead to on-site manufacturing and building in difficult-to-access or dangerous locations such as post-disaster relief construction, tall buildings, or infrastructure.

Weitzman Assistant Professor of Architecture and Penn Engineering GRASP Lab-Affiliated Faculty Robert Stuart-Smith, through his Autonomous Manufacturing Lab at Penn and its sister lab in University College London’s Department of Computer Science, contributed to the project.

The research was developed by a consortium of researchers led by Professor Mirko Kovac from Imperial College London and Empa and the Swiss Federal Laboratories of Materials Science and Technology, together with Co-Investigators Robert Stuart-Smith, Stefan Leutenegger, Vijay Pawar, Richard Ball, Chris Williams and Paul Shephard, and their research teams at Imperial College, University College London, University of Bath, University of Pennsylvania, Queen Mary University of London, and Technical University of Munich.

Kovac said, “We’ve proved the concept that drones can autonomously work in tandem to construct and repair buildings, at least in the lab. This scalable solution could help construction and repair in difficult-to-reach areas, such as post-disaster reconstruction or tall buildings.”

Aerial-AM uses both a 3D printing and path-planning framework that enables a team of drones to adapt to variations in the geometry of a structure as manufacturing progresses. Throughout printing, the drones assess already printed geometry in real time and adapt their behavior to ensure they meet the build specifications and manufacturing tolerances. The drones are fully autonomous in flight, but there is a human controller in the loop who can monitor progress and intervene if necessary.

Proof-of-concept prints were developed including a 2.05-metre cylinder (72 layers) with a polyurethane-based foam material, and an 18-centimetre cylinder (28 layers) with a custom-designed structural cementitious material.

The technology offers future possibilities for building and repairing structures in unbounded, high or other hard-to-access locations. Next, the researchers will work with construction companies to validate the developed solutions and provide repair and manufacturing capabilities. They believe the technology will provide significant cost savings and reduce access risks compared to traditional manual methods.

The work was funded by the Engineering and Physical Sciences Research Council, part of UKRI. It was launched by Stuart-Smith and Kovac after a pilot research collaboration, and an award for a demonstration on pipeline repair. The project is also supported by Industrial Partners Skanska, Ultimaker, Burohappold, and BRE.

The work is the subject of a new article in Nature, “Aerial Additive Manufacturing with Multiple Autonomous Robots” by Zhang et al., published September 21, 2022.

Expand Image

Expand Image