September 26, 2024

Toward Carbon-Negative Architecture

Can 3D-printed buildings act as carbon sinks? A multi-institutional team led by Penn faculty thinks so.

By Matt Shaw

Concrete is the second most-used material in the world. A multi-disciplinary team of researchers from Weitzman and Penn Engineering are working to develop a new building system that would reduce carbon in all aspects of concrete construction. (Photo iStock.com/SeventyFour)

Close

Concrete is the second most-used material in the world. A multi-disciplinary team of researchers from Weitzman and Penn Engineering are working to develop a new building system that would reduce carbon in all aspects of concrete construction. (Photo iStock.com/SeventyFour)

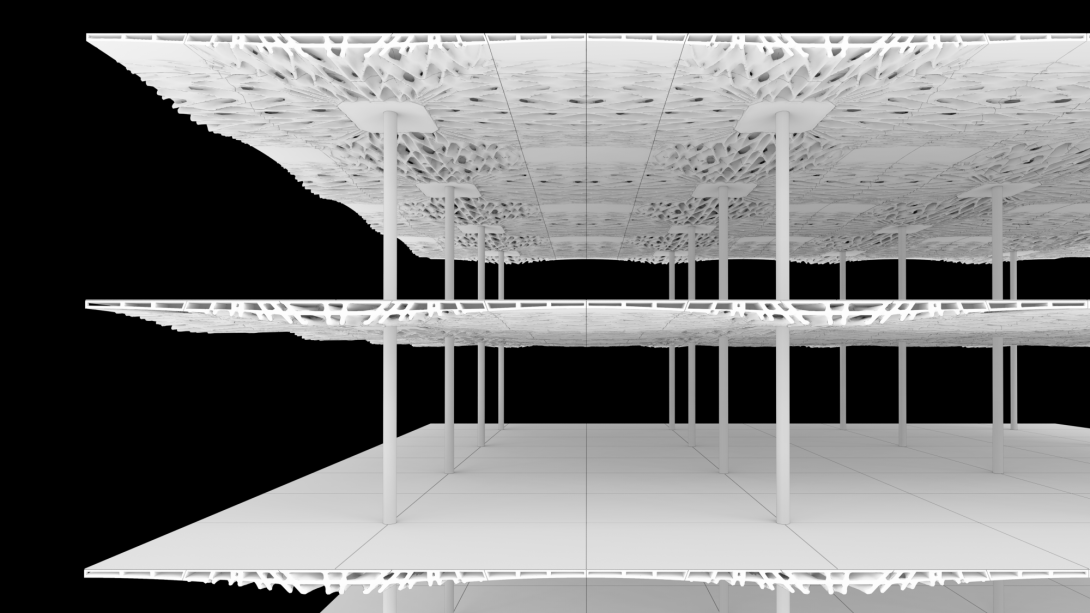

A prototype of the 3D-printed concrete structure, which is made up of multiple slabs, is load tested at Weitzman's Polyhedral Structures Lab.

The performance of the slab geometry is measured experimentally in a controlled climate chamber, comparing the TPMS geometry to a conventional flat slab.

A computational fluid dynamic simulation by the Thermal Architecture Lab studied the surface temperature variation of the slab across the geometry during cooling.

View Slideshow

View Slideshow